Kamtech Industrial Drives

Hydraulic System Service & Repair

Houston, Texas

Phone: 936-537-5334

Email: kam-tech@consolidated.net

Hydraulic System Service & Repair

Houston, Texas

Phone: 936-537-5334

Email: kam-tech@consolidated.net

Copyright © KamtechDrives.com

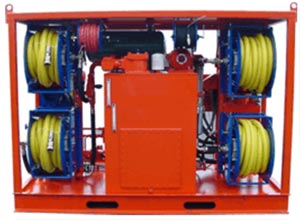

System Flushing & Pressure Testing

HYDRAULIC SYSTEM CLEANLINESS HAS ALWAYS BEEN A CRITICAL FACTOR IN REGARD TO PERFORMANCE AND SERVICE LIFE. TODAY'S HYDRAULIC SYSTEMS REQUIRE FLUID CLEANLINESS LEVELS SET FORTH IN NATIONAL AEROSPACE STANDARD -NAS-CLASS 8 OR EQUIVALENT ISO:DIS 4406 CLASS -16/13. HYDRAULIC SYSTEM COMPONENT MANUFACTURERS WILL NOT WARRANT THEIR PRODUCTS WITHOUT PROOF OF THE CONTAMINATE LEVELS.

SYSTEM FLUSHING GENERALLY FALL INTO TWO CATEGORIES:

NEW INSTALLATIONS

SYSTEM FLUSHING GENERALLY FALL INTO TWO CATEGORIES:

NEW INSTALLATIONS

NEW SYSTEMS SHOULD UTILIZE FLOW HIGH RATES TO MEET THE REYNOLDS NUMBER (TURBULENT FLOW) BASED ON THE PIPING INNER DIAMETER.

THE KAM-TECH FLUSHING UNIT MEETS THESE FLOW REQUIREMENTS FOR PIPE DIAMETERS UP TO FOUR INCHES.

THIS UNIT FEATURES A PRESSURE TESTING CAPABILITY UP TO 10,000 PSI AND CONTAMINATE COUNT DOCUMENTATION.

THE KAM-TECH FLUSHING UNIT MEETS THESE FLOW REQUIREMENTS FOR PIPE DIAMETERS UP TO FOUR INCHES.

THIS UNIT FEATURES A PRESSURE TESTING CAPABILITY UP TO 10,000 PSI AND CONTAMINATE COUNT DOCUMENTATION.

BREAKDOWN & SMALL INSTALLATIONS

SYSTEMS WHICH HAVE BEEN IN OPERATION AND HAVE SUFFERED A MAIN COMPONENT FAILURE SHOULD BE FLUSHED PRIOR TO INSTALLATION AND START-UP OF THE REPLACEMENT COMPONENT

KAM-TECH UTILIZES A PORTABLE FILTER UNIT IN COMBINATION WITH PARTICLE COUNTER. FLOW IS SUPPLIED BY THE ACTUAL EXISTING SYSTEM VIA RE-ROUTING PLUMBING.

THIS APPROACH IS IDEAL IN BREAKDOWN SITUATIONS AND CAN BE MOBILIZED QUICKLY

KAM-TECH UTILIZES A PORTABLE FILTER UNIT IN COMBINATION WITH PARTICLE COUNTER. FLOW IS SUPPLIED BY THE ACTUAL EXISTING SYSTEM VIA RE-ROUTING PLUMBING.

THIS APPROACH IS IDEAL IN BREAKDOWN SITUATIONS AND CAN BE MOBILIZED QUICKLY